“From independent service technician to leading supplier: Herbert Barsch founded Barsch and developed customized flowpack machines."

Company foundation

+ 50

Years experience

6

VW Bullis

1986

Company foundation

1

Company dog

Management

Frank started at Barsch with an apprenticeship as a precision mechanic and subsequently completed a dual study program in the field of systems engineering up to a master's degree. He is responsible for design and ensures that production runs smoothly.

As a team, they complement each other perfectly and, as experienced managers, they ensure smooth production and the continuous further development of our flowpack machines.

“Nadine and Frank successfully manage Barsch with complementary skills and many years of experience in the company.”

+ 450 cups

coffee drunk together

2010

work together since

3 h

Stand set-up in record-breaking

+ 10

Flat jokes on a Friday

"Barsch supplies personalized flowpack machines to horticultural companies and international groups, with modular design and excellent service. "

Customers

Our unique selling point is our modular machine construction, which enables us to adapt each machine individually to the needs of our customers. In doing so, they benefit from our many years of experience. We attach great importance to service availability in order to always be able to offer our customers, especially those who supply sensitive foods to the food retail sector, a contact person and a quick solution.

+ 250

Number of customers

12

Countries

80 %

in the fruit and vegetables sector

+ 30

Number of industries

Work culture

In addition, a good fault trace is very important to us. Since we use the same assemblies over and over again, it is important to troubleshoot in a structured manner so that the operating process is continuously improved.

“Structured project planning, detailed documentation and a good error culture guarantee smooth production at Barsch.”

+ 130

Number of implemented CIP proposals

+ 20

Number of checklists we have

1 x

So often we may make mistakes

100 %

conscientious documentation

"We promote the continuing education of our employees through semi-annual discussions and individual development plans."

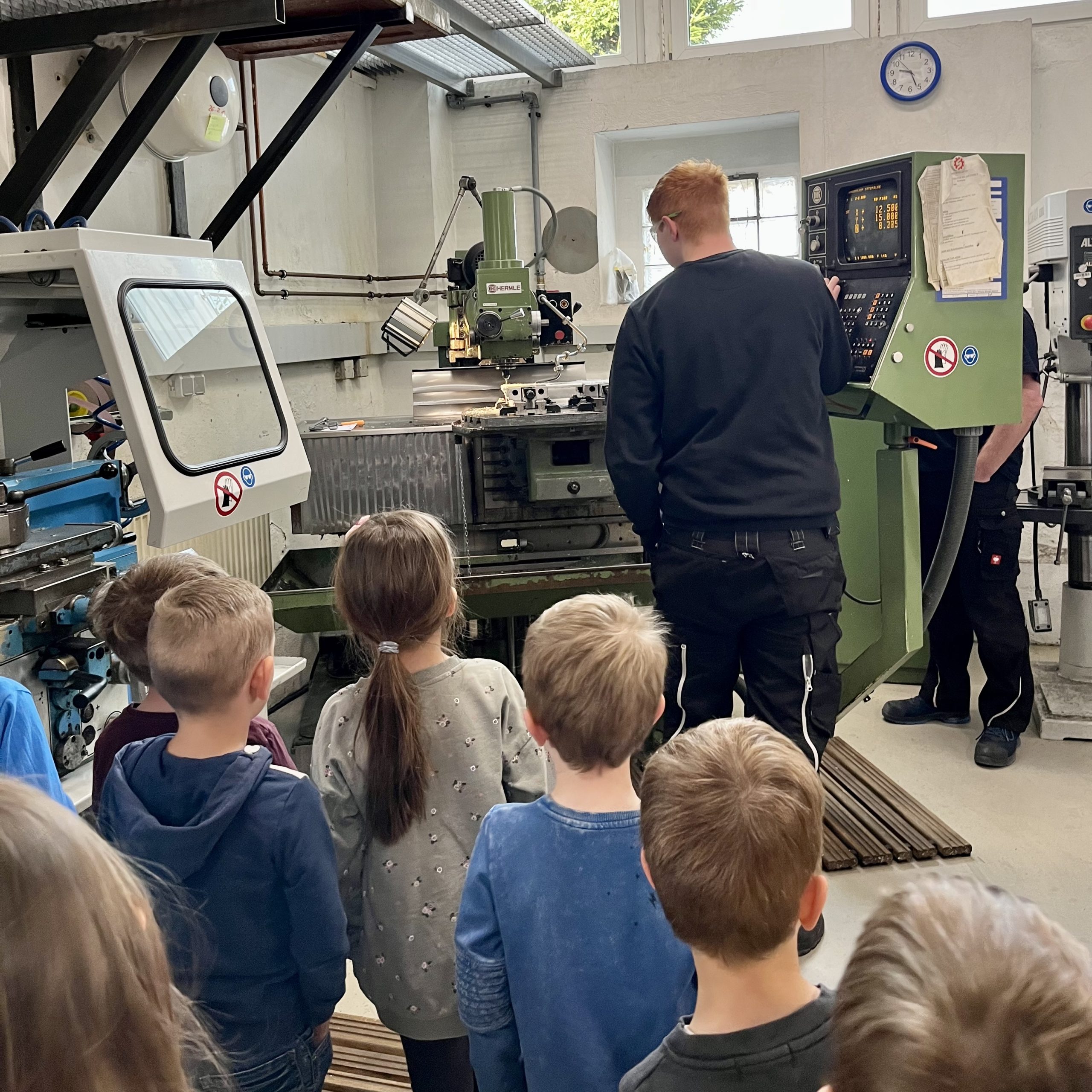

Career Opportunities

2

Employee reviews per year

2

open positions

2

Number of apprenticeships

100

Possibilities of further development

Compensation and benefits

“With us, employees receive fair salaries and benefit from great additional services."

300 €

Workwear budget per year

2

Job bikes

100 %

Orientation to IGM tariff

1

Coffee machine

"Our working conditions are state of the art. With us you work in a modern environment."

Working conditions

9

Height adjustable desks

1

Water bubbler

3

curved screens

1986

Documents digitalized since

Team and cooperation

"Collaboration and celebration - at our company, both are part of the corporate culture."

2

Company parties per year

18

Number of employees

1

Breakfast together per month

1

90's music in the workshop a month